Other benefits of pumping over

- Aeration of the must to increase and activate the yeasts.

- Preventing the cap from drying to avoid the formation of bacteria and mould on the surface.

- Keeping the cap cool (the skins in the cap can reach high temperatures and pumping over cools them down and helps prevent the growth of thermophilic bacteria).

- Distribution of the yeasts.

- Extraction of substances from the skins, especially tannins, colours and aromas.

The seeds of the grapes gather at the bottom of the tank during fermentation and, unlike the skins, carbon dioxide cannot make them float to the surface. Therefore, it is necessary to pump them up onto the top of the cap so that more of their tannins can be extracted.

The number of times and frequency with which the wine needs to be pumped over in each tank is decided by the oenologist depending on the grape variety, fermentation phase and the wine being made.

The ideal pump for pumping over

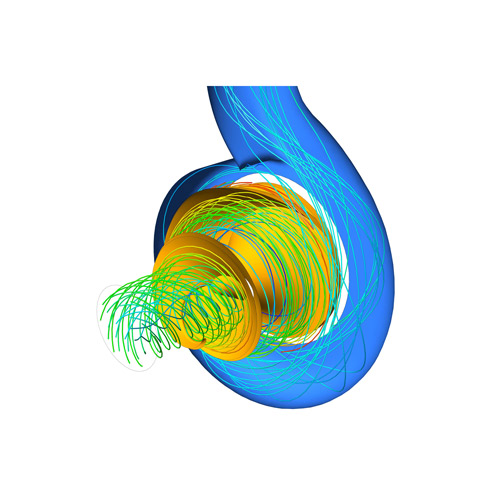

To perform the process of pumping over in the best conditions, INOXPA offers the RV range of centrifugal pumps with helicoidal impeller.

These pumps are ideal for pumping over since they are designed to pump high flow rates of liquids with solids in suspension and avoid damage to the solids (different sizes depending on pump size, maximum particle size ø = 75 mm).

Advantages of RV pumps

- Lower energy input to the wine: thanks to their excellent design with CFD tools, they obtain very high performance levels (>70%). This means a lower increase in the temperature of the pumped liquid.

- Low energy consumption thanks to their high performance.

- Minimal damage to solids (skins, seeds, pulp...): the helicoidal impeller and the very precise clearances between the impeller, cover and pump casing guarantee minimum recirculation inside the pump and let solids through without damaging their structure.

- Easy maintenance.

- No need to place a grid to serve as strainer in the tank.

- CE-1935/2004 and FDA compliant food grade materials.

- Motor in compliance with the IEC standards (RV version) and with NEMA standard (RVN version).