PIG product recovery systems: Sustainable savings

29/01/2026

SystemsINOXPA invests great efforts in sustainability, which is why we design our components and systems to achieve higher energy efficiency by reducing water consumption and waste generation as well as decreasing process costs.

We are aware of the importance of a good hygienic design that minimizes contamination risks, facilitates cleaning and contributes to conserving and maintaining the components and systems.

With this in mind, we research production materials, pay attention to the type and finishes of the surfaces that come into contact with the product, and ensure component accessibility for inspection and maintenance, as well as necessary drainage, sealing and efficient cleaning.

In any process plant, there are a multitude of components and systems with different functions but a common goal: to optimise the process they are used for and make it more profitable. INOXPA’s R&D department is constantly studying and improving all our components and systems with the aim of achieving this objective. This quest for resource optimisation includes saving water and, consequently, caring for the environment.

Water is an extremely valuable, needed resource, but unfortunately, it is increasingly limited and scarce. For this reason, demands by international organisations for the moderation of its consumption and processing have increased, with the aim of avoiding overexploitation and counteracting the droughts we are suffering.

If any system stands out above the others when it comes to achieving these objectives of savings and commitment to the environment, it is the PIG.

CIP (clean-in-place) or SIP (sterilisation-in-place) cycles generally take place after a product processing cycle in order to clean or sterilise all of the inner surface of pipes before starting the next process.

These cleaning cycles start by rinsing and expelling product residue – generally in large quantities – with the twofold waste that this incurs: loss of useful product and loss of large quantities of water.

With the installation of a product recovery system, this pre-rinse phase and product waste are reduced to a minimum.

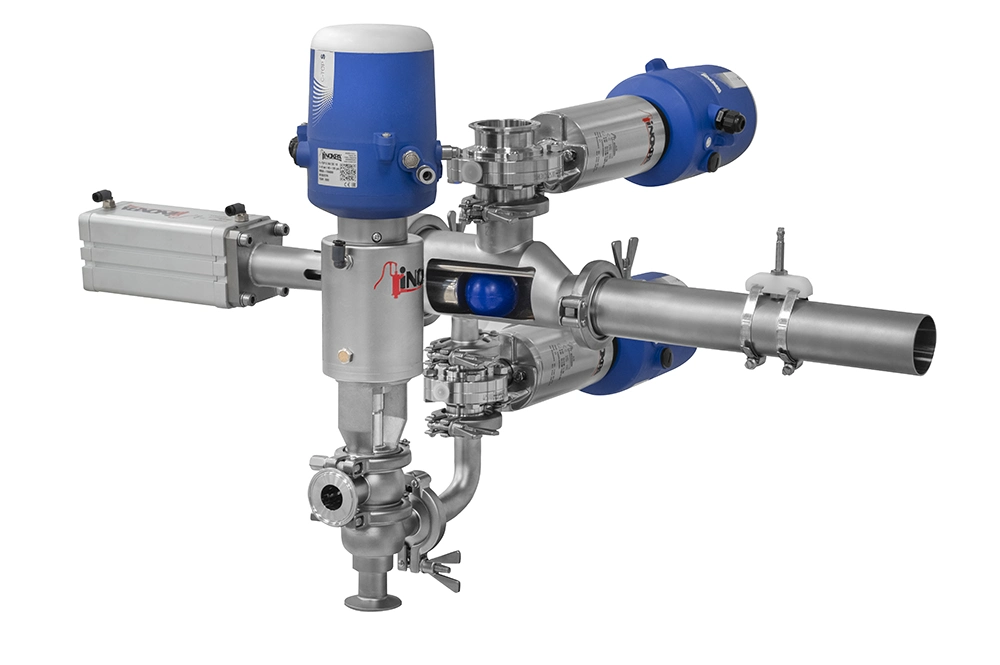

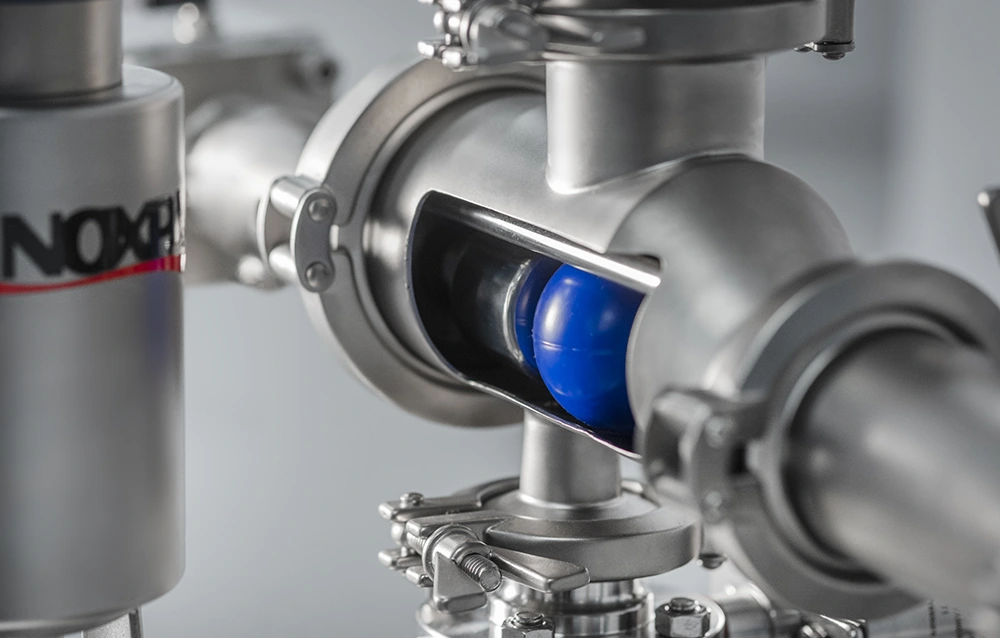

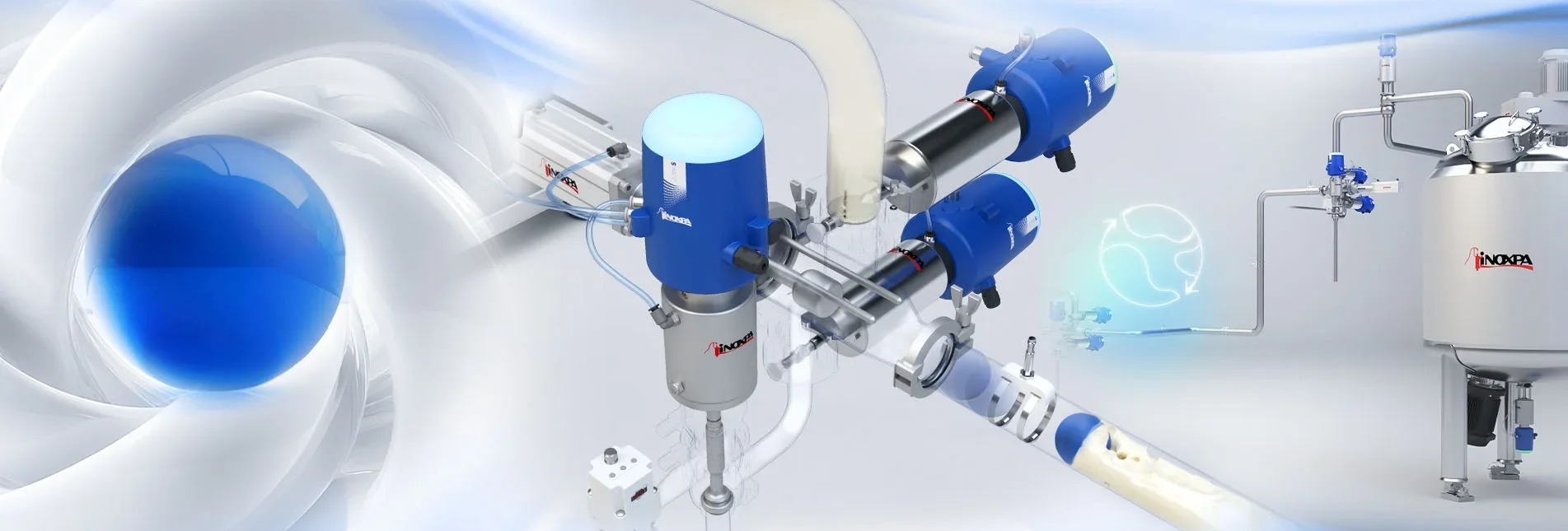

The INOXPA product recovery system consists of a launcher and a receiver, both with the same configuration, and a main element, the PIG, in the case of INOXPA, it is a sphere. The PIG is made from various elastic materials – silicone, NBR and EPDM – allowing it to adapt perfectly to the inside of pipes and recover up to 98% of the remaining product.

The system is fully automated and digitalised thanks to the incorporation of control units for all the valves of the system and centralised connections for its management.

In this way, the flow of the product is controlled using butterfly valves and the entry of the propulsion element and the drainage is controlled using INNOVA KH divert seat valves.

The launcher, via a pneumatic system with magnets, positions the PIG at the entrance to the pipe, from where it is launched by a propellant, which can be water, air, carbon dioxide or nitrogen.

The PIG travels through the entire pipe, recovering the product as it goes, until it reaches the receiver. There, the PIG is received and repositioned ready to be sent back to where it started. This is when the CIP cleaning cycle takes place. Once it is finished, the PIG is returned by the same propulsion system, back to the launcher.

It is important to point out that the product can travel hundreds of metres during the full process, from the reception of raw materials to the transport, storage and filling phase. This can cause product to accumulate in the pipes, making efficient cleaning systems essential.

A PIG system is an excellent investment, since it starts paying off from the very first minute of operation.

Key strengths:

- Recovery of product that can have significant economic value

- Drastic reduction in required volumes of water and cleaning products

- Decrease in cleaning times and, consequently, reduction in costs and increase in production times

- Easier, faster, safer and more effective cleaning

The first profit-driving factor is the recovery of very high quantities of product. For example, a calculation for a facility with 50 metres of DN80 piping with a daily cleaning cycle shows that 250 litres per day would be recovered, amounting to some 50 000 litres per year.

By reducing volumes of water and cleaning products, we not only achieve savings and profit for the company; we also make a significant contribution to caring for the environment by decreasing water usage and the generation of waste in terms of processed products and aggressive cleaning agents.

Such waste requires subsequent treatment, and when the need for this treatment is reduced thanks to the PIG system, this also benefits both the company and the environment.

Reducing cleaning cycle times increases the time available for production, meaning that the PIG system increases plant efficiency.

Lastly, since 98% of the remaining excess product is removed from the pipes, cleaning is easier as well as more efficient and effective.

This type of system can be installed in new plants and adapted to existing facilities. In this case, the facility in question must meet certain requirements. The pipes must have a constant diameter with no obstructions or valves that hinder passage through the internal space. This means that any butterfly valves must be replaced by ball valves that allow full passage.

Thanks to the INOXPA PIG system, major multinational companies are managing to recover a ton of product in a single day from a single plant – at the same time as achieving institutional recognition for their contribution to sustainability in the form of awards and grants.

Without a doubt, the INOXPA PIG system is a great investment that will bring about major economic and environmental benefits wherever it is installed.

Contact

Other news

-

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

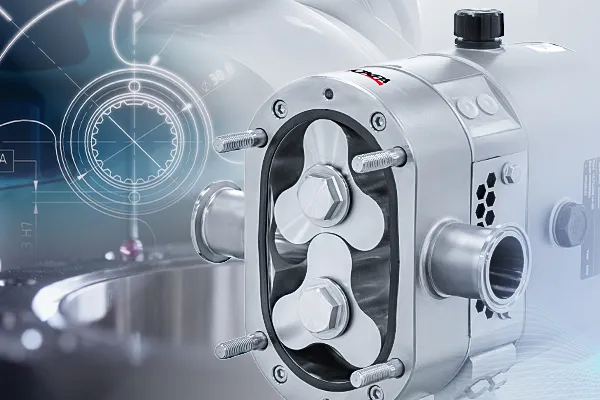

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps -

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems