Legumes, cereals, nuts, seeds and other raw materials from vegetable origin are used to extract into water a concentrated plant-based liquid which is employed as a base for the formulation of plant-based drinks.

Additives such as oils, minerals, vitamins, flavours can be added to the final formulation to improve the nutritional properties as well as taste and texture.

Based on raw material, capacity and final product formulation, the design of the process plants may differ significantly.

INOXPA offers made-to-measure solutions to satisfy the most demanding requirements in terms of process, automation, capacity and construction features. A great number of options for the customisation of any part of the process are available for any customer to have the right tools to make his product unique and successfully marketed.

Besides process and plant engineering, INOXPA offers technological support to optimise existing products or develop new ones to allow our customers to be present in the market with quality and innovative products.

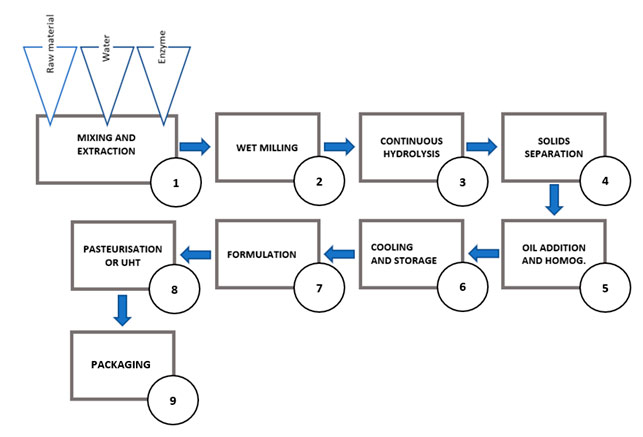

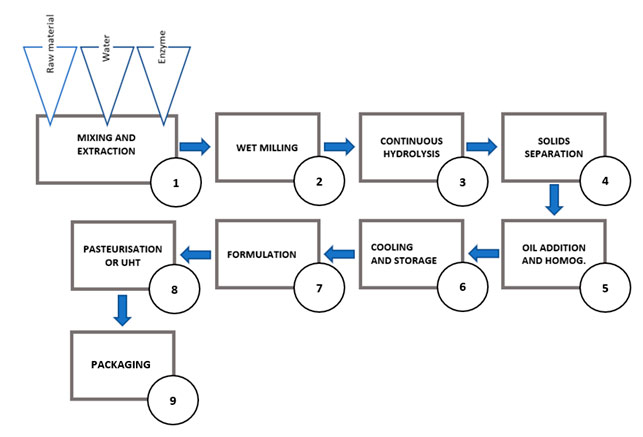

Typical plant-based process:

1. Temperature/time/flow rate-controlled, continuous mixing and extraction of concentrated plant-based liquid.

2. Wet milling.

3. Hydrolysis to achieve gelatinisation, liquefaction and saccharification through a temperature/time-controlled process.

4. Separation of suspended solids using centrifuge/centrifuges.

5. Oil blending and homogenisation.

6. Cooling and storage of concentrated extract.

7. Formulation of final product: dilution, ingredients addition, flavouring, etc.

8. Pasteurisation/UHT treatment.

9. Packaging.