Latest news

-

New INNOVA single seat valves

22/03/2024INOXPA is launching a new range of single seat valves with significant design and feature innovations and improvements.

-

New plant in France

31/01/2024INOXPA inaugurated a new plant in France, facilitating an increase in engineering capacity, conducting FAT tests and equipment tests in the pilot plant.

Products

Case studies

Find out how we help both small and large companies of this industry achieve their goals.

Bioreactors for the biotechnology industry

Design, manufacture and installation of two bioreactors for producing beneficial microorganisms for agricultural applications.

Automated SLES dilution unit

Tailor-made solution for the autonomous, safe dilution of concentrated SLES, with programmed recipes for producing cosmetics.

Upcoming trade shows

-

Applications

We have the right solution for your process

-

Food industry

-

Bakery industry

-

Dairy industry

-

Beverage industry

-

Cosmetic and pharmaceutical industry

Our most recent videos

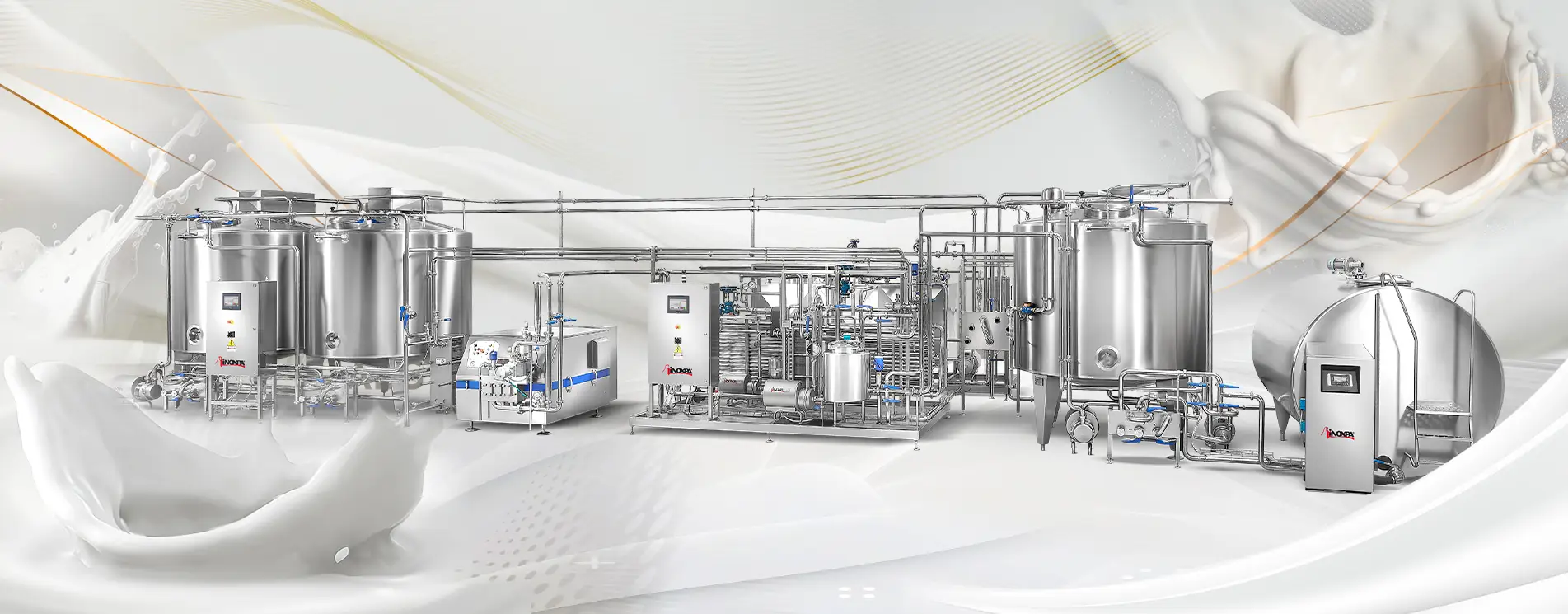

INOXPA excels in the production of skids and turnkey plants for the food, dairy, beverage, cosmetic and pharmaceutical industries.

We offer the highest level in manufacturing, installation, automation and start-up processes.

Manufacturing our own skids and components means we can ensure the highest quality of all our products.

Services

INOXPA offers every customer support and advice before, during and after purchase. INOXPA’s range of services help customers select the product that best meets their needs from the outset, and how to use it correctly afterwards: planning, installation, training, problem-solving, maintenance and repair, updating and modernising.

-

Start-up

-

Support

-

Improvements

-

Maintenance

-

Customer service

INTERPUMP GROUP

-

Billions of € in turnover

-

Employees

-

Group companies

-

Turnover invested in R&D

-

Countries of the world where we sell directly